|

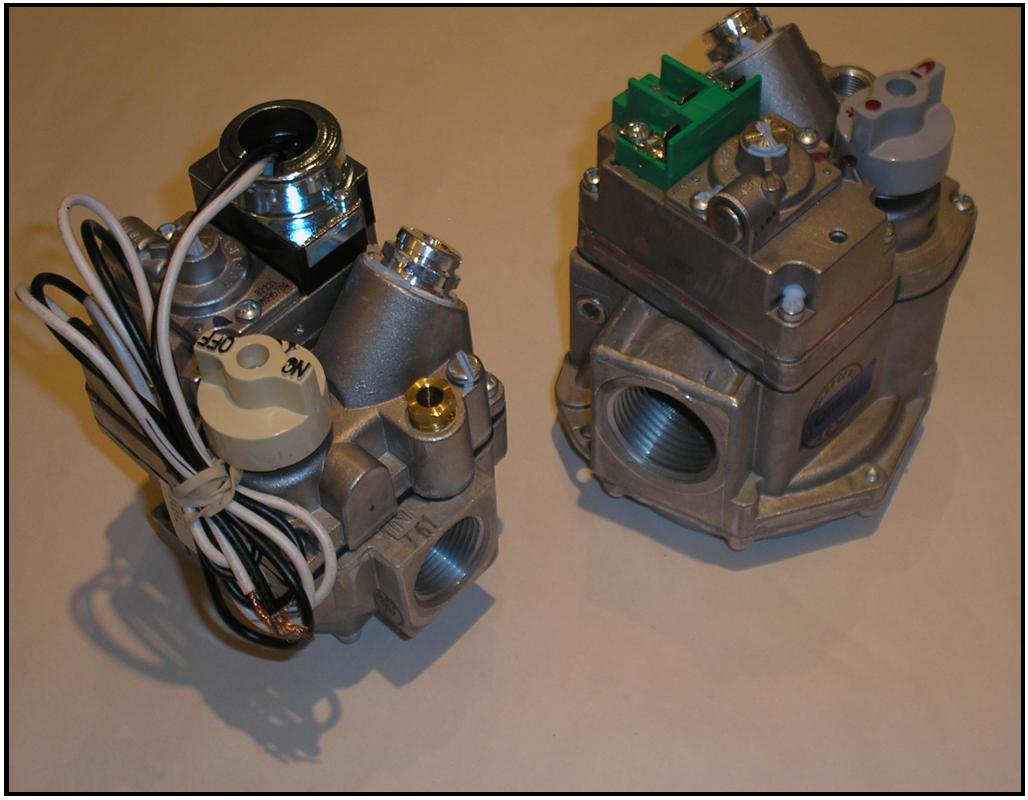

CDR Technical Services now offer an extensive range of

versatile Unitrol 7000 series gas valves for heating and

commercial catering applications. This range of gas

valves are designed to provide a permanent pilot burner

and regulated control of the gas flow to the main

burners.

The Unitrol 7000 series incorporates a rotary gas cock,

flame supervision device working in conjunction with a

permanent pilot, governor (when specified) and ON/OFF

control.

The main gas flow is controlled a number of options such

as an electric operator (24V or 240V), a Thermopile

generator or by incorporating a gas Thermostat.

The Unitrol 7000 gas valve range are fully approval to

CE, UL,CSA certification.

Typical

Unitrol 7000 Gas Valve.

Features & Components:

Unitrols are robust "Straight Line" gas controllers,

design for easy installation.

Compact design, with easy replaceable parts.

Available in a variety of designs to suit pipe size and

operating system supply.

|

|

Typical Range of Unitrol 7000 series Valves

|

General

Data |

|

Frame/Housing |

Aluminium die-casting |

|

Inlet/Outlet |

1/2", 3/4" or 1" Standard |

|

Operator System |

Millivolts, Gas Operators,

24v or 240volt |

|

Safety Approval |

UL, CSA, CE |

Accessories:

Thermostat or

Thermocouple Magnets - designed with internal thread to

ensure correct thermocouples or thermopile is used.

Magnets are slotted to accept interrupter leads.

Governor (Regulator)

- Add on pressure regulator kits are available for the

Unitrol series (except hydraulic models which have

regulators built in). Each type provides "straight line"

regulation features. Kits include gasket, mounting

screws and instructions.

Replacement Operators

- The Unitrol gas valve has components that can be

readily exchanged. It is essential when replacing

components the the procedure instructions are adhered

too at all times.

Control Knobs - A

variety of replacement control knobs/dials are

available.

Blanking Plates -

Used in place of Governor where governor is required. ie,

were pressure is regulated in application elsewhere, as

in normal practise in LPG applications. |